River Keekle Bridge

- Masonry arches crossing the River Keekle in Cumbria had become cracked due to differential movement between the parapet and masonry barrel arch

- A repair was designed to stabilise the cracked barrel soffit utilising SockFix grouted anchors

- Diamond Drilling was utilised to minimise the structure’s exposure to vibration

- With the 52 anchors in place, grout tubes were cut off below the face of the stonework and replaced with a colour-matched core

- This complex repair ensured that there was no aesthetic change to the bridge

Background

Where the B5295 crosses the River Keekle, there are two masonry arches. One of these spans the river while the other lies over a public footpath. This area is prone to flooding and the footpath acts as an overflow for the river. As a result of differential movement between the stiff parapet sections and the masonry barrel arch, the second arch was suffering from circumferential cracking of the barrel soffit and crown. The client had proposed stitching the crack using ties rods and external pattress plates but grouted anchors were suggested as a better solution.

Grouted anchors were used to stabilise the cracked barrel soffit without altering the appearance of the bridge.

The Project

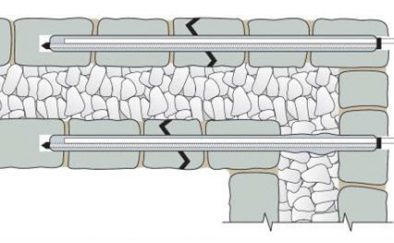

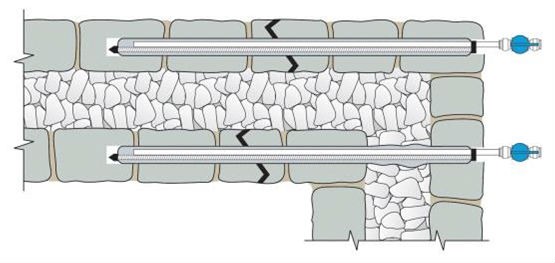

The masonry arch had a span of 7.3 metres and was constructed from squared, random rubble, snecked sandstone masonry. In order to repair the crack, the SockFix system was deployed. This system uses grout-filled socks combined with a threaded bar which expands in order to form a strong bond with the substrate.

The repair involved installing grouted anchors into the voussoirs on both sides of the arch in order to stabilise the cracked barrel. A mixture of 2m, 2.5m and 3m grouted anchors were installed.

Diamond Drilling was deployed in order to core the holes with minimal vibration and ensure that the structural integrity is maintained.

Grout was injected at low pressure in order to ensure that no additional pressure was put onto surrounding masonry and that any void had no impact of the effectiveness of the anchors, ensuring the bond was strong between the internal and external leaves.

Diamond Drilling was deployed in order to core the holes with minimal vibration and ensure that the structural integrity is maintained.

The drilled cores were retained and used to cover the anchor installation ensuring that the repair was not visible to the untrained eye. Once the anchors had cured, the grout tubes were removed in preparation for the installation of the colour-matched core. These steps ensured that the bridge was repaired with no discernible changes to its appearance.